Jagnath Plot, Rajkot, Gujarat

- GST NO. : 24AFMPR2626G1ZE

+91-9879574372 Call / WhatsApp |

View Mobile Number Call Us |

devprecisionengineers@gmail.com Drop us a line |

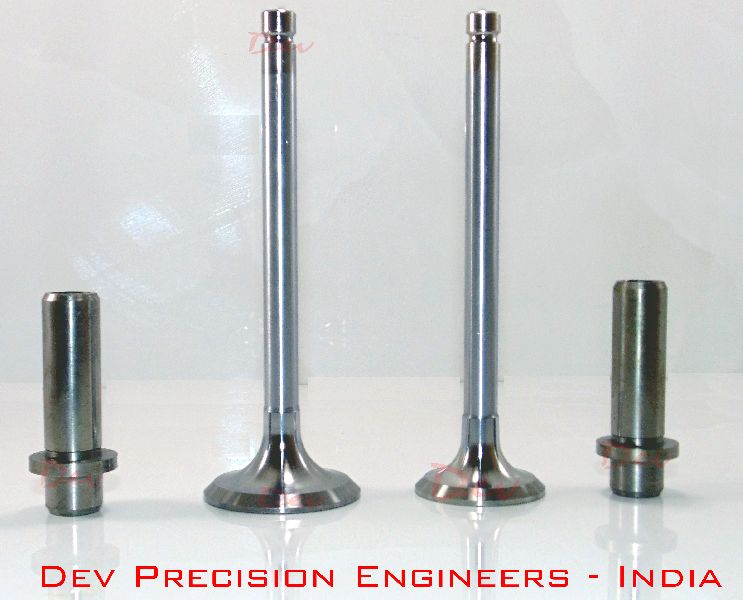

Engine Valve

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Bukh Engine DV20 DV10 Valves, Bukh Engine DV24 DV36 DV48 Valve Guide, Engine Exhaust Valve, Engine Inlet Valve and Engine Valve Guide Seat from Rajkot.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Metal |

| Application | Engine Use |

| Color | Silver |

| Feature | Easy Maintenance. |

| Weight | .4 kg |

| Dimensions | 6 × 6 × 14 cm |

| Brand Name | Dev |

Besides these we can also supply following Parts : - Big End Bearings Part No 40563 / 000E 0563 DV20 DV24 DV29 DV36 DV32 DV48 - Main bearing liner Part No 000E 4765 / 000E4765 DV36 - Bukh DV24 DV29 DV32 Engine PISTON Assembly 008E7679,

Bukh DV20 DV10 Valves for Marine Engine 000E9113 Inlet and 000E9114 Exhaust Valve.

- A high quality replacement Valve Pair for Bukh DV 2 Cylinder and 1 Cylinder Marin diesel Engine.

- Engine Valves Pair is suitable for Bukh with Bore X Stroke – 3.35″ x 3.35 in (85 x 85 mm)

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Engine Valve Guides |

| Material | Metal |

| Application | Engine |

| Color | Metallic |

| Country of Origin | India |

| Weight | .4 kg |

| Dimensions | 6 × 6 × 5 cm |

| Brand Name | Dev |

Besides these we can also supply following Parts : - Big End Bearings Part No 40563 / 000E 0563 DV20 DV24 DV29 DV36 DV32 DV48 - Main bearing liner Part No 000E 4765 / 000E4765 DV36 - Bukh DV24 DV29 DV32 Engine PISTON Assembly 008E7679,

- Bukh DV24 DV36 DV48 Valve Guides.

- Bukh engine Inlet Exhaust Valve Guide Part No 000E4878 pair for Bukh DV24 DV36 DV48.

- A high quality replacement Valve Pair for Bukh DV 2 Cylinder and 3 Cylinder Engine.

- Inlet and Exhaust Engine Valve Guide Pair is suitable for Bukh marine Diesel Engine.

- Bukh DV24, DV24 RME, DV29, DV29 RME, DV32, DV32 RME, DV36, DV36 RME, DV48 and DV48 RME Valve guide.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Metal |

| Length | 100-200mm |

| Application | Engine Use |

| Pressure | High Pressure, Medium Pressure |

| Feature | Casting Approved, Durable, Investment Casting |

| Warranty | 1yr |

| Brand Name | Dev |

We offer an all encompassing range of valves, which contains intake valves, exhaust valves and engine valves. Our engine valves are manufactured using superior quality chrome plating / valve steel series- EN18D, EN24, EN52, EN54, EN59(214N) (Non-Magnetic/Bimetal) with varied hardness from 20HRC to 50HRC. Available in over sizes, these engine valves are extensively used in automobiles, tractors, industrial & diesel engines, generators and two wheelers.

Our intake and exhaust valves are manufactured from a variety of materials to be operated under different conditions. These valves are manufactured using super Material Carbon steel, martens tic steel with chrome and silicon, stainless martensitic, stainless austenitic, Inconel and Nimonic. These valves are available in different dimensions & material as per the usage and the application of the valve.

Normally, our intake valves are manufactured from high quality alloy steel, as these valves are not exposed to the corrosive action of the hot exhaust gases. Consequentially, these intake valves provide the users long time hassle free service. For manufacturing exhaust valves, we use chromium silicon, which makes them resist to corrosion due to high temperature and hot gases.

Various type of heat treatments its definition and objective

It is defined as an operation or combination of different operations involving heating and cooling of metal or an alloy in solid state for the purpose of obtaining certain required structures and desirable properties of a combination of properties suitable for the particular application.

Heat treatment is carried out to achieve one or more of the following objects:

- To relieve the stresses set up in the material after hot or cold working in order to improve machine ability.

- To improve mechanical properties like tensile strength, hardness, ductility, shock resistance etc.

- To modify the structure of the material to improve its electrical and magnetic properties.

- To increase the qualities of a metal to provide better resistance to heat, corrosion and wear.

Following heat treatment processes are mainly in use for achieving most of the objects of heat treatment:

- Annealing

- Spheroidising

- Normalising

- Hardening

- Tempering

- Case hardening or surface hardening

- Carburising

- Nitriding

- Cyaniding

- Induction hardening

- Flame hardening

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Available In Different Sizes |

| Material | Metal |

| Certification | ISI Certified |

| Application | Engines |

| Feature | Casting Approved, Durable |

| Surface | Polished |

| Pack Type | Carton Box |

| Brand Name | Dev |

We are one of the eminent valve guide manufacturers and suppliers in India, who manufacture and supply a wide range of valve guide. The valve guide offered by us is manufactured from optimum quality raw material, so as to ensure the quality & durability of the final product. We provide comprehensive range of quality engine valve guide, which can be used in different engines. We manufacture and supply a wide range of valve guides widely used for automobiles, tractors, industrial & diesel engines. We manufacture valve guide in various material depend on :-

- Customer requirement

- Type & Size of engine

- Engine R.P.M. & effort of engine

- Their application where used

Material of Valve Guide as we use :-

- Copper zinc alloy

- Phosphorous Bronze and leaded bronze

- Manganese Bronze

- Aluminium Bronze (North American UNS C95400, German CuAI10Fe, British AB1) for high temperature applications.

- Gun Metal

- Alloy Graded Cast Iron of 25 & 30 Grade. This Cast Iron is specially made for High Racing Engine.

- Tin Bronze (North American UNS C90500, German CuSn10Zn, British G1) for piston airplane engines.

Cast Iron is a general term applied to a wide range of iron carbon alloys. Their carbon content is such as to cause some liquid of eutectic composition to solidify. The maximum carbon content is therefore about 2% while the practical maximum is about 4.3%

Cast Iron should not be thought of as metal having single element. It should at least posses’ six elements. These are iron, carbon, silicon, manganese, phosphorus and sulphur.

Some of the important mechanical properties

- Brinell Hardness Number (b.h.n) = 150 to 225

- It is a brittle material.

- It cannot be beaten in sheets or rolled or forged. Hence it is not a malleable material

Various types of Cast Iron are as follows:

- Grey Cast Iron

- White Cast Iron

- Mottled Cast Iron

- Malleable Cast Iron

- Spheroidal Grey Iron (s.g.iron)

- Inoculated Cast Iron

- Alloy Cast Iron

Addition of nickel to cast iron produces fine grains, helps formation of graphite and prevents formation of white hard iron nickel & copper ensure an austenitic structure. Chromium and silicon add resistance to scaling. The microstructure of iron is stabilized and formation of fine graphite is promoted by the addition of chromium. The matrix of cast iron is strengthened through promotion of the fine pearlite by the addition of molybdenum.

Valves developed from CuZnAl-alloy & grey cast iron alloy with high phosphorous content to offer high wear resistance as well as improver the years working properties in poor lubrication conditions. The inner bore of these valve guides is finished to perfect size, not usually done by competitors.

CuZnAl-alloy Guides are with excellent wear resistance and low coefficient of friction. Used for highest stressed guides. While developing these valve guides, we pay care full attention to the

accurate dimensions, so that they could meet with the OEM standards.

Our valve guide has hardness in range of 160 225 BHN. ValveGuide has microstructure of matrix pearlite with 5% free ferrite. We also provide thread or spiral in inner diameter of valve guide to retain oil for long time between valve and valve guide & increase life both. Our valve guide are grounded to a surface finish 0.80 micro ra value on its outer dia & maintain outer diameter within tolerance of 12 microns. Our valve guide has Super Finish Bore.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Available in Different Sizes |

| Material | Metal |

| Application | Engine Use |

| Surface | Grinning, Plating |

| Features | Casting Approved, Durable, Investment Casting |

| Length | 100-200mm |

| Pressure | High Pressure, Medium Pressure |

| Warranty | 1 Year |

| Brand Name | Dev |

We are one of the eminent valve guide manufacturers and suppliers in India, who manufacture and supply a wide range of valve guide. The valve guide offered by us is manufactured from optimum quality raw material, so as to ensure the quality & durability of the final product. We provide comprehensive range of quality engine valve guide, which can be used in different engines. We manufacture and supply a wide range of valve guides widely used for automobiles, tractors, industrial & diesel engines. We manufacture valve guide in various material depend on :-

- Customer requirement

- Type & Size of engine

- Engine R.P.M. & effort of engine

Their application where usedMaterial of Valve Guide as we use :-

- Copper zinc alloy

- Phosphorous Bronze and leaded bronze

- Manganese Bronze

- Aluminium Bronze (North American UNS C95400, German CuAI10Fe, British AB1) for high temperature applications.

- Gun Metal

- Alloy Graded Cast Iron of 25 & 30 Grade. This Cast Iron is specially made for High Racing Engine.

- Tin Bronze (North American UNS C90500, German CuSn10Zn, British G1) for piston airplane enginesCast Iron is a general term applied to a wide range of iron carbon alloys. Their carbon content is such as to cause some liquid of eutectic composition to solidify. The maximum carbon content is therefore about 2% while the practical maximum is about 4.3%Cast Iron should not be thought of as metal having single element. It should at least posses’ six elements. These are iron, carbon, silicon, manganese, phosphorus and sulphur.

Some of the important mechanical properties

- Brinell Hardness Number (b.h.n) = 150 to 225

- It is a brittle material.

- It cannot be beaten in sheets or rolled or forged. Hence it is not a malleable material

Various types of Cast Iron are as follows:

- Grey Cast Iron

- White Cast Iron

- Mottled Cast Iron

- Malleable Cast Iron

- Spheroidal Grey Iron (s.g.iron)

- Inoculated Cast Iron

- Alloy Cast Iron

Addition of nickel to cast iron produces fine grains, helps formation of graphite and prevents formation of white hard iron nickel & copper ensure an austenitic structure. Chromium and silicon add resistance to scaling. The microstructure of iron is stabilized and formation of fine graphite is promoted by the addition of chromium. The matrix of cast iron is strengthened through promotion of the fine pearlite by the addition of molybdenum.

Valves developed from CuZnAl-alloy & grey cast iron alloy with high phosphorous content to offer high wear resistance as well as improver the years working properties in poor lubrication conditions. The inner bore of these valve guides is finished to perfect size, not usually done by competitors.

CuZnAl-alloy Guides are with excellent wear resistance and low coefficient of friction. Used for highest stressed guides. While developing these valve guides, we pay care full attention to the accurate dimensions, so that they could meet with the OEM standards.

Our valve guide has hardness in range of 160 225 BHN. ValveGuide has microstructure of matrix pearlite with 5% free ferrite. We also provide thread or spiral in inner diameter of valve guide to retain oil for long time between valve and valve guide & increase life both. Our valve guide are grounded to a surface finish 0.80 micro ra value on its outer dia & maintain outer diameter within tolerance of 12 microns. Our valve guide has Super Finish Bore.