Jagnath Plot, Rajkot, Gujarat

- GST NO. : 24AFMPR2626G1ZE

+91-9879574372 Call / WhatsApp |

View Mobile Number Call Us |

devprecisionengineers@gmail.com Drop us a line |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Metal |

| Length | 100-200mm |

| Application | Engine Use |

| Click to view more | |

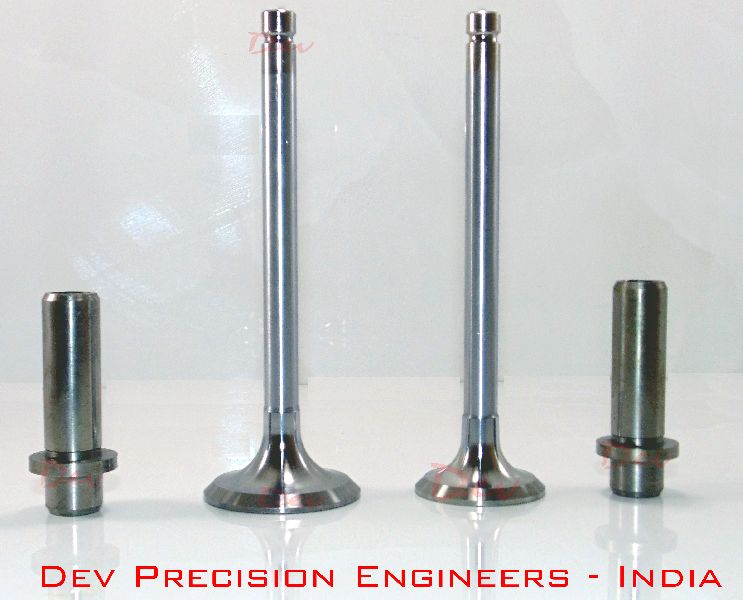

Product Details

We offer an all encompassing range of valves, which contains intake valves, exhaust valves and engine valves. Our engine valves are manufactured using superior quality chrome plating / valve steel series- EN18D, EN24, EN52, EN54, EN59(214N) (Non-Magnetic/Bimetal) with varied hardness from 20HRC to 50HRC. Available in over sizes, these engine valves are extensively used in automobiles, tractors, industrial & diesel engines, generators and two wheelers.

Our intake and exhaust valves are manufactured from a variety of materials to be operated under different conditions. These valves are manufactured using super Material Carbon steel, martens tic steel with chrome and silicon, stainless martensitic, stainless austenitic, Inconel and Nimonic. These valves are available in different dimensions & material as per the usage and the application of the valve.

Normally, our intake valves are manufactured from high quality alloy steel, as these valves are not exposed to the corrosive action of the hot exhaust gases. Consequentially, these intake valves provide the users long time hassle free service. For manufacturing exhaust valves, we use chromium silicon, which makes them resist to corrosion due to high temperature and hot gases.

Various type of heat treatments its definition and objective

It is defined as an operation or combination of different operations involving heating and cooling of metal or an alloy in solid state for the purpose of obtaining certain required structures and desirable properties of a combination of properties suitable for the particular application.

Heat treatment is carried out to achieve one or more of the following objects:

- To relieve the stresses set up in the material after hot or cold working in order to improve machine ability.

- To improve mechanical properties like tensile strength, hardness, ductility, shock resistance etc.

- To modify the structure of the material to improve its electrical and magnetic properties.

- To increase the qualities of a metal to provide better resistance to heat, corrosion and wear.

Following heat treatment processes are mainly in use for achieving most of the objects of heat treatment:

- Annealing

- Spheroidising

- Normalising

- Hardening

- Tempering

- Case hardening or surface hardening

- Carburising

- Nitriding

- Cyaniding

- Induction hardening

- Flame hardening

Looking for "Engine Exhaust Valve" ?

Explore More Products